Topic

Why few freestanding Cuben Tents?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Why few freestanding Cuben Tents?

- This topic has 113 replies, 11 voices, and was last updated 5 years ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Feb 17, 2020 at 6:44 pm #3631829

as the panels on a tunnel need to stretch a bit when it is erected

To clarify for others: there are two reasons you need a bit of stretch in tent fabric. The first is to absorb small irregularities in the sewing: deviations of 1 – 2 mm in the stitch line. They happen. The second is to create a ‘pre-load’ in the fabric able to handle wind buffeting. You can put tension in a DCF panel, but there is little or no difference between slack and taut in the panel. With nylon there is a lot of ‘reserve capacity’.there are times and places in the Presidential range in NH when one cannot stand up, and some may want a shelter that can tolerate just about anything.

Oh, we get plenty of that here in our Alps is Oz. In my article ‘When Things Go Wrong’, I mention crawling around in the morning to strike the tent. Does this mean the tent has some extra weight? Well, yes, but we sleep soundly! We carry that extra weight (470 g) quite willingly.When you get tornado force winds, I hope you will head for a storm cellar or the like,

Thank you for the thought, but we don’t have storm cellars in Sydney. Solid brick walls and heavy tile roof. Plus lots of tie-downs between the roof beams and the walls!Cheers

Feb 19, 2020 at 9:24 pm #3632204Hi Roger,

Got the idea that you were taking shelter in one of your tunnel tents from your comment that:“Storms: we got 200 mm (8″) of rain in under 48 hours here recently, along with tornado-force winds (which flipped one of our horse sheds upside down). Quite OK in one of my tunnels (assuming a drained site!), but I want to see someone manage … that in a single-pole DCF pop-up or in a bivy.”

I like the solid bricks and tiles better. No requirement to minimize weight if you don’t have to carry them in your pack, and am sure your designs are just as good with brick and mortar.

Have got the lightening of my pop-up almost figured out. Just need to increase the angle of the rear peak elbow and voila!, the rear of the tent drops. Duh! With some scale and full size models, can get the exact angle for the rear elbow, depending how much the rear peak will be dropping. I think one foot, or down to a three foot height will still allow sitting up in the back of the tent; but want the peak four feet high at the front for easy access and inside space.

For those who are interested, the problem of how to make a pop-up that will stay dry inside while pitched in the rain, was addressed by sewing the WP vestibules directly to the breathable, but solid inner ceiling. The DWR on the ceiling keeps water out during the pitch, and the fly just covers the ceiling portion, plus extensions to protect the vent openings at the tops of the vestibules. So the fly is much smaller, and much easier to attach in high winds, unlike the situation in your video where the guy is chasing the fly. Lots of heresies here, I know, and haven’t even mentioned lots of devilish details, but those can be ironed out (the details not the cherished heresies). :)

Feb 19, 2020 at 11:22 pm #3632222Storm (yet another) two days ago. Lost power for 36 hours. Back on now.

Bushwalking stoves to the rescue.The men with chainsaws and chipping machines are making a fortune these days. People renting out generators are also doing well. A change from selling fire-fighting pumps …

Sam: your design – need drawings to visualise.

Cheers

Feb 21, 2020 at 8:03 am #3632398Structurally speaking, it certainly makes sense to have a “stretchable” fabric work in tandem with a flexible pole, based on the materials used in tent design.

But what if one were able to increase the stiffness of the pole independent of the stretching of the fabric? In a building, one of the greatest attributes of steel is both it’s super high stiffness while remaining a little flexible. (Although it can deform if too much stress is applied.)

But is the flexible poles were became stiffer without loosing their deformity, then one wouldn’t need to “depend” on stretchable fabric as much.

(in theory)

Feb 21, 2020 at 2:13 pm #3632481what if one were able to increase the stiffness of the pole

That is easy to do, but there is always a weight penalty of course.Actually, I find steel quite soft and bendy compared to carbon fibre for instance. When you compare the two on a weight for weight basis, steel becomes very soft. This is reflected in their Young’s Modulus.

My carbon fibre tent poles, as used in both summer and winter tents, are 7.5 mm OD and about 6.2 mm ID. They look very thin, but they work. If you went up to something like 10 mm OD and 8 mm ID, they would be close to ‘rigid’, but heavier.

Overall, UL gear is using close to the highest performance materials already: carbon fibre, nylon 6,6, titanium alloy, Spectra and Dacron, 95% down, PET, silicone coatings, …

Cheers

Feb 21, 2020 at 11:48 pm #3632584Hi Roger,

Here is the latest scale model:

The model is mostly for visualization, as you requested. The rear peak has been dropped 8″ from the 4 foot high front peak, and the rear peak elbow angle increased to 150 degrees compared to 120 for the front peak elbow . This allows for a much smaller and lighter rear vestibule for storage space – the foam block in the photo represents a pack. One other thing with the scale model (1″ = 1′) is the dimensions can be determined, and the weight of the fabric calculated as part of a weight estimate for the tent.

Left the rear vestibule with two pegs as you suggested. The flexible poles in the model are music wire, and will be made from Gold Tip carbon Expedition Hunter 75/95 shafts for the actual tent. But I don’t make them until the exact length is determined using some ancient SMC light alloy poles. The wooden sticks do not represent poles – just seam lines, which are inaccurate, as a catenary cut will be put in the vestibule seams during construction.

The weight penalty for a ridge pole will be 1.16 oz, not counting ferrrules, end tips, and shock cord. Due to the slope of the ridge, I don’t think this design will pool water on top, but a ridge pole will help greatly with shedding snow, and will strengthen the structure. The ridge pole will project over the peaks to hold up vent awnings, but on the model is just represented by a short wooden stick between the peaks – vent construction to come later. It will be made from Easton carbon Axis 500 shafts that are lighter and more flexible than the Gold Tip shafts.

This design does not require a wooden construction frame because the main canopy assumes its bowed out shape when stretched over the frame, as the fabric will stretch more on the bias than with the grain. The vestibules are another matter, but once the main frame is built, and the fabric attached over it, a wooden frame has not been necessary to make the vestibules on other tent projects.

The fabric is still in question, but the 1.06 oz Extreme Textil 20D silnylon looks good. It should be a lot stronger than lower denier fabrics and almost as light. Figure a weight penalty of 0.36 oz/sq/yd over the 0.7 oz Rockywoods 7D, the lightest of the 7D fabrics AFAIK. But won’t decide until I finish testing and post on the ExTex, and see what others may say.

So this is pretty off-piste, inasmuch as an unwoven material like DCF, would not bow out on the bias (not without a heat gun, hah-hah).

Bought a roll-out generator and transfer switch years ago due to the constant power outages in our neighborhood. A quick story. When we built a new county courthouse, I tried to get a generator put in, but was denied. At the building dedication, all the muckety-mucks showed up, but during the ceremony, the power went out, and stayed out. My boss was secretly amused because he had joined me in trying to get the generator. ‘I-told-you-so’s’ are deemed unseemly, but we had a good laugh later.

Feb 22, 2020 at 12:58 am #3632594I think that ridge pole might be a very good idea. Whether it needs to stick out front or back is another matter – I don’t know.

Cheers

Feb 23, 2020 at 12:16 am #3632759Once the ridge pole is flexed to create a convex ridge, it will shed precipitation better; but there is the danger of the pole rotating in high winds and/or heavy snow to create a concave ridge. Supporting the vent awnings is nice, but they also anchor the flexed ridge pole so it won’t rotate under pressure.

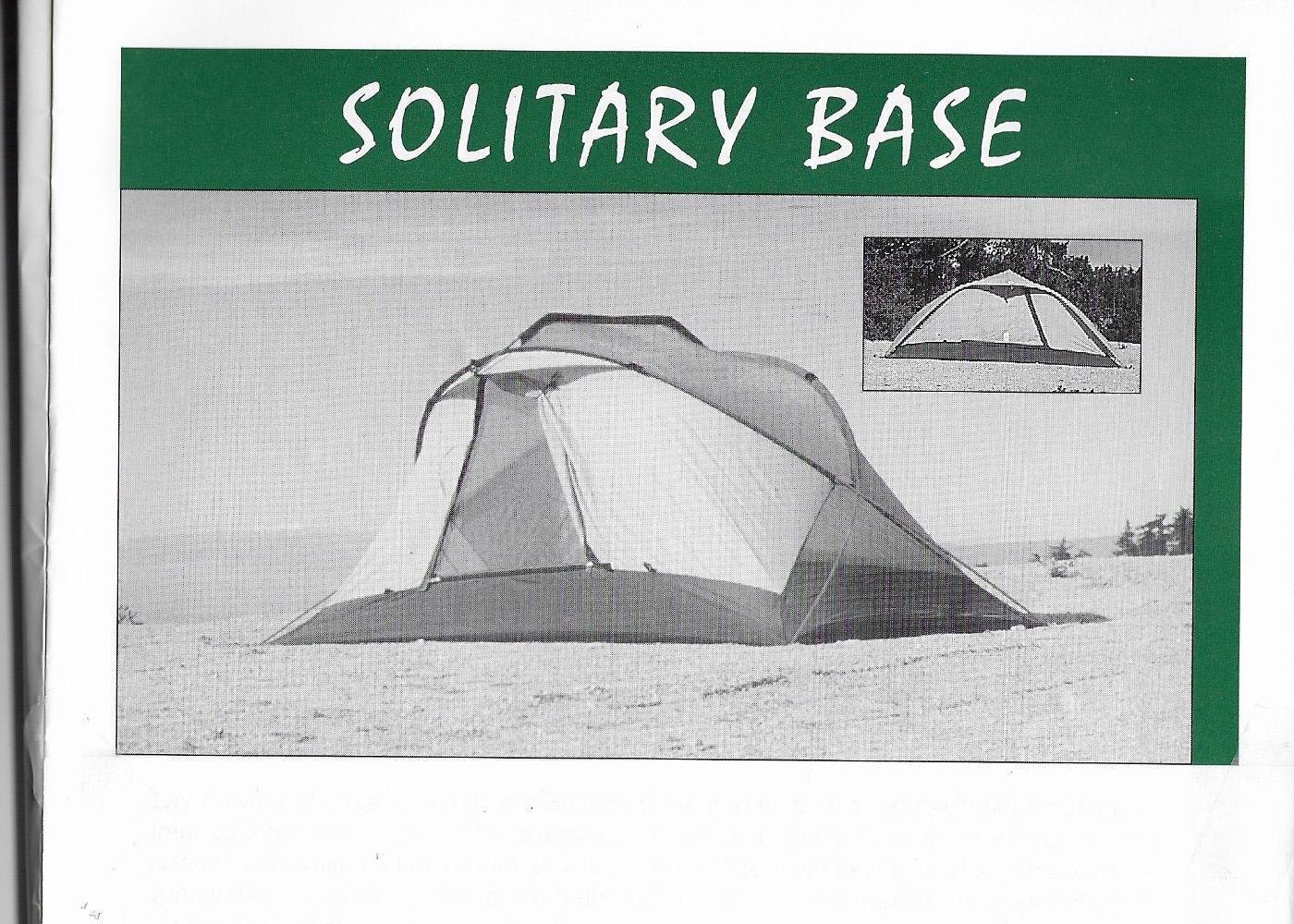

One of the tents that addressed this issue was made by Steve Noall and was called the ‘Solitary Base.’ It also used the vent awnings to stabilize the ridge pole, but instead of being flexed into an arc, it had two pre-bends that served as elbows. It looked like this:

The bends were sharp enough to keep the ridge pole solidly in place. But I think one could do as well with a pole flexed in an arc. And that’s the reason for the extensions; not just to support the vent awnings, but also to stabilize the ridge pole in its sleeve, not to mention supporting the fly overlapping the peaks and the inner tent underneath. Whether Steve Noall’s sharper angles on the ridge pole are needed remains to be seen.It was already noted on this thread that trekkertent (spelled as one word) makes traditional domes with the poles crossing only once at the top center, and that they can be ordered in DCF, and also in silnylon, about 10 ounces heavier. And they have a nice version of the old Phoenix Phreeranger, similar to the TarpTent Rainbow, that also comes in DCF.

But after doing the math, I also think that my pop-up can come in close to 2 lbs in silnylon, without using DCF, and using 20D Extrem Textil silnylon for the vestibules, adding less than 1.6 oz to what the vestibule weights would be using 3/4 oz DCF. Great for those who wish to pack small, as well as light. Granted, many can now pack with solo tents close to a pound using DCF and trekking poles for tent poles. But they may not be as stable in heavy winds and precipitation as better designed pop-ups and tunnels. That may have been part of what the OP was thinking about.

Thank you for bringing us to greater appreciation of tents that function well in severe weather, in winter as well as other seasons.

Feb 23, 2020 at 3:18 am #3632765there is the danger of the pole rotating in high winds and/or heavy snow to create a concave ridge.

Hum, yes.

You could glue fixtures to the end(s) of the ridge to prevent this

OR

you could accept this as part of the design?Cheers

Feb 23, 2020 at 10:21 pm #3632947Thanks, Roger. Will ponder it some more.

Feb 24, 2020 at 10:28 am #3633010“One of the tents that addressed this issue was made by Steve Noall and was called the ‘Solitary Base.’”

I vividly remember Steve Noall’s tents back in the early 90’s. They seemed to carry a reputation of being very well made tents back in the day. I especially remember the Mountaineer II (even though I felt it was a little short for me:)

Of course when it came out, it seemed like a tweaked variant of the Moss Stardome:

Which was simply a four season version of the early 80’s Stargazer:

(Sigh….)

Feb 26, 2020 at 4:34 pm #3633337The older tents were heavier, not designed for very light weight, even if the new materials had been available.

Then came the ‘side-entry’ tents, which apart from being more comfortable, could be made much lighter for the amount of internal space provided.

Searched Google for the Mountaineer II without success. And they think we believe that they’ve got everything. Everybody, maybe, but not everything. Noall’s later tents were something else, and it was right around the advent of lighter silnylon when he went on to other things. Spoke with him then, and he was wrapping it up.

Was a fan of Moss tents as well, with 3 or 4 of them. Sold the last one a few years ago at a friend’s yard sale. Very sturdy, but lighter and more spacious options had arrived.

Have been trying to design to use the fabric portion of a tent to stiffen the poles, as illogical as that may sound. Saves a lot of weight by dispensing with very rigid poles. DCF versions would be more rigid still. But not sure if that would be a plus. A moderator somewhere on gear media said something about flexibility increasing strength.

Feb 26, 2020 at 5:02 pm #3633339Matt already posted a photo of the Mountaineer, here are another 2

Feb 27, 2020 at 3:13 pm #3633466

Feb 27, 2020 at 3:13 pm #3633466That looks like a really neat design, Franco. Thank you.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.