Topic

Why few freestanding Cuben Tents?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Why few freestanding Cuben Tents?

- This topic has 113 replies, 11 voices, and was last updated 5 years ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Jan 27, 2019 at 4:19 pm #3575321

“Trekking pole tents save weight by not using dedicated tent poles. But then they have to add weight back since they do not use fabric as efficiently….you’d have to add in 2-3oz or more fabric weight to get a similar amount of useable volume in a trekking pole tent.”

I have to mostly disagree here. The most fabric efficient tent shape is a dome, but trekking pole tents can come surprisingly close to this if they are an optimal design.I wrote a really geeky blog post about this recently:

https://intocascadia.com/2019/01/08/the-volumetric-efficiency-of-trekking-pole-shelters/In short, the difference in fabric usage between an efficiently designed trekking pole tent design and a dome tent is about 0.5oz for a given volume. Then a more traditional poled tent realizes about half of that difference, about a 0.2 – 0.3oz difference for a given volume.

But indeed there are many inefficient trekking pole designs out there. In my post I compare and discuss a wide range of configurations and show how much of a difference it makes. Indeed the difference could be 2oz if you have something volumetrically inefficient like a single pole mid.

Jan 27, 2019 at 4:50 pm #3575325<p style=”text-align: left;”>Maybe the XMid design is an exception for useable volume. Not sure how the High Route from Sierra Designs fairs. Other companies have to resort to struts to improve useable volume.</p>

Even though you can calculate volume, poled tents often feel roomier to me because there is no pole in the way. My Solomid felt much roomier when pitched in an inverted-V, even though the volume was the same as when pitched with one pole.Jan 27, 2019 at 5:13 pm #3575328The HR would be about halfway between the X-Mid and the pup style tent, because the poles are at the perimeter (more boxy) but not all the way to the ends.

Agree that’s poles can impede on space and make it feel smaller. But like pitch complexity, it is very specific to the design. Many trekking pole shelters have poles in the living space, are hard to pitch and volume inefficient, but they don’t have to be. It seems like a lot of designers don’t pay much attention to these things.

Jan 29, 2019 at 2:55 pm #3575649Any experiences with the ZPacks Duplex Flex (with tent- instead of trekking) poles?:

http://www.zpacks.com/shelter/duplex-flex.shtmlDoes look quite unstable for me on the picture, but could be an interesting option for those who are not using trekking poles (like me f.e. …).

Jan 29, 2019 at 5:10 pm #3575670I’ve spent quite a bit of time thinking about using Duplex/Flex style poles on a trekking pole tent because I was considering doing something similar with my tent. I haven’t used the Duplex/Flex system myself, but I’ve often camped with people that are, and spent a fair bit of time looking it over.

In general, trekking pole designs don’t translate very well to a system like this because a trekking pole tent always has “peaks” whereas a poled tent is normally a more gently curved shape. So you have to do weird things with the pole set that compromise it’s rigidity. With the Duplex/Flex, Zpacks felt the need to split the pole set into two non-connected halves, so the pole set loses a lot of ridgidity at the peaks where the two halves abut, but don’t solidly join like a dome tent. There’s a fair bit of play there. It works but it wouldn’t take that much of a wind gust to flatten one.

I think for most folks opting for straight poles is better even if they don’t use trekking poles. That’s going to be lighter and ultimately more stormworthy. The Flex poles do pull it out into a nice shape (e.g. you can get a better angle on the mid panel guyouts) and it is freestanding which can be nice if the ground is poor or hard to find a flat spot, so there is a place for it, but most non-trekking pole users will be better suited with straight poles.

Jan 29, 2019 at 6:17 pm #3575682Thats what I think too, having the Flex Poles AND trekking poles could be quite an interesting option too. I wonder why it has 4 poles btw., should be possible with 2 long poles from the curvature IMO? No sharp bends or so in the way.

OT: Dan, I’d love to see a Silpoly (X-Mid style?) tent with tent poles from you, just to let you know :)

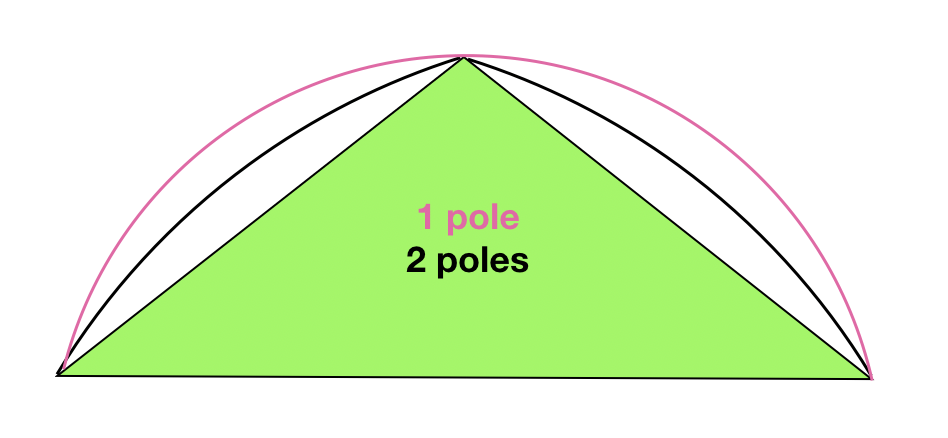

Looking forward to test the X-Mid anyway ;)Jan 29, 2019 at 11:46 pm #3575738The problem with doing 2 long poles is that due to the peaks, the poles get quite a bit further from the body. Here is an illustration that is admittedly poor for several reasons, such as being 2D, but it shows the main point:

You can see that it gets pretty far from the walls on either side, so even if you connect it to the tent via longer cords, there’s still a lot of room for the poles to deflect side to side. So it works but it would be even more flexy in some ways and less flexy in others. Overall I’m not sure it would be an improvement.To actually do this, you’d need to have the poles laid out something like this (arial view):

But with the poles that sideways, I doubt they’d have very much upward pull on the peaks so I think you’d still have a very flexy tent. It would flatten easily. I guess better would be crossing poles like a typical dome tent, and then add a cross strut at the top (basically a Big Sky Revolution or MSR Hubba Hubba). That would look funny though because the center of the X would need to be a few inches higher than the peaks, so it would be way higher than the center of the ridgeline. If you were serious about using the tent like this a lot, you’d re-shape it to be like a MSR Hubba Hubba.All of this highlights the importance of thinking things through from first principles. If Zpacks designed a tent from the ground up for traditional tent poles, they would use a curved (dome) roof line instead of peaked (see the top image, but imagine the green area the same shape as the pink pole). So basically a single wall MSR Hubba Hubba. That would weigh about the same but add a ton more headroom inside because dome tents are more volumetrically efficient. It would also be a lot more rigid because the pole set and tent would be closely matched in shape (and other reasons). Obviously they haven’t done so because this is just intended as a secondary ability for the Duplex, but if someone were to buy a Duplex with this intended as its primary usage, then they’d be better off with a tent that was designed from the ground up for that. I know Big Sky works with DCF sometimes and has some single wall designs similar to this.

As it pertains to the X-Mid, the first prototype did have grommets at the corners and numerous connection points along the seams to enable an external pole set like Zpacks Flex set. But it became clear that this was a clumsy way to go because I was trying to do something that wasn’t a part of the core design. It would have worked okay – about as well as the Flex set – but far worse than a tent designed specifically for this. So kept the X-Mid limited to what it is best at. Perhaps someday I’ll have the opportunity to design a tent that primarily uses traditional poles. The problem with designing a tent is that you want to design so many more because there are so many niches. I’ve love to do 1P and 2P, silpoly and DCF, 2 pole design / 4 pole design / freestanding design etc.

Feb 1, 2020 at 11:48 am #3629481I’m late to this thread, and many probably already know about it, but the Locus Gear Djedi is a 2-pole dome tent made with an eVent hybrid DCF and comes in at 30.69 oz without additional mesh door and 34.22 with mesh door – for $1,159 (!!) and $1,306 (!!!!), respectively, at today’s exchange rate of 1 Japanese Yen = $0.0092.

As a counterpoint, I hacked my regular eVent Black Diamond FirstLight down from 49.6 oz to 33.2 oz just by going to CF poles, appropriately sized tie-out cordage (300 lb. Dyneema vs. cheap 1/8″ paracord), and 6 mini Groundhog stakes vs. the 6 supplied stakes, for a total cost of $457 ($350 tent + $95 CF poles + $12 stakes).

For my purposes, there are several big advantages to “freestanding” domes vs. all other designs:

- High altitude “winter” use – domes are by far the best aerodynamic and snow-shedding shape

- Maximum volume for amount of fabric used: lower weight, lower cost, less surface area exposed to cold air

- Minimum footprint – best for use on tiny ledges and where snow must be stamped/shoveled level

- Minimum footprint to usable volume ratio

- When designed for it, ability to assemble from the inside, out of the elements

No doubt the Djedi is stronger and includes mid-side tie-outs, but I’ve used the FirstLight in sustained 60 mph + 80 mph gusts wind conditions with no problem – other than my nerves!

The biggest problem with all the 2-pole dome tents I’ve seen is lack of ventilation = too much condensation in warm, humid conditions. I’m currently prototyping an all-DCF design that I hope will solve this issue.

Feb 1, 2020 at 11:34 pm #3629561You’re pretty much reading my mind @gearmaker. After 24 years of hard usage, my original Bibler itent and I are inseparable. My ideal is a much lighter weight version of essentially the same thing. The djedi looks great, but the price point, gulp.

My frustration with ul trekking pole tents is the relatively large footprint and rats nest of cordage required for a shelter that is still fairly fragile and only works well when the pitch is perfect.

The number of nights the itent has saved my bacon by being a quick and compact pitch in a difficult situation is significant. Pull it out, crawl inside and pop in poles. Done and solid.

The only issue is weight. I realize this is probably a small market, but I’m honestly a bit surprised at that.

Feb 1, 2020 at 11:43 pm #3629564Missed a piece and can’t seem to edit my post above.

The modded first light you describe is pretty close to what I’m looking for, but my impression is their quite a bit more fragile than the itent and reportedly not waterproof. That’s a must for me. Still finding the gap in free standing, storm worthy offerings well, a gap.

Feb 2, 2020 at 9:51 am #3629587

You know you want one…

Feb 2, 2020 at 10:04 am #3629589@edhyatt: which tent is that?

Feb 2, 2020 at 10:45 am #3629593Feb 2, 2020 at 10:48 am #3629594Feb 2, 2020 at 10:28 pm #3629661That’s about $830 US for a DCF simple dome.

Re: “I think it would be cool if the rain “flys” of some freestanding tents were made of Cuben.”

Was confronted with this issue. But will use 20D silnyon,1.06 osy, for the two vestibules, front and rear, where there is a greater chance of wear due to traffic. But will use Rockywoods 7D sil/PU nylon for a separate fly over the main tent, about 0.7 osy, and no bonding required except for the reinforcement patches. How much is DCF going to improve on that with 0.8 osy, or even 0.5 osy?

Don’t think DCF is difficult to cut. On the two swatches I sent to Stephen S. to test, a simple utility knife, albeit with a fresh blade, sliced through it much easier than nylon, where I do better with very sharp Fiskars, that slide right along the cut lines.

Other than that, however, agree with all the reasons why DCF is or could be much more expensive to manufacture in a simple dome; hence more expensive to sell. Hence $830 US.

But do not agree that the DCF is all that lighter than a range of 0.7 to 1.06 osy for sil nylon or sil/PU nylon. Pick a ballpark sq/yd number for a simple dome, do the math, and see what you get.

Add to that the abrasion resistance, puncture resistance, longevity and stuff size issues, not to mention concerns about deformity in the hot sun. So DCF has more tear resistance. Problem is, no one including our moderator has reported a nylon canopy ripping apart, unless from a broken pole puncture, and at that point the tent must be taken out of service to be repaired, And I’ll bet the DCF would puncture from the same event, so with either Nylon or DCF it would be a matter of patching in a wind and/or rain storm.

I think there is a mystique about the DCF from the tear resistance demos that ignores vulnerability to aging, punctures and abrasion. Sure, the dyneema fibers may be many times stronger than steel, but they are not woven into a fabric, and between the dyneema fibers there is nothing but mylar that is more fragile than saran wrap. The burden should be on the industry to show reliable evidence of durability vs nylon in terms of long term resistance to abrasion, puncture and wear; so let’s see it.

In the meantime, we should be just as happy with our silnylon tents, sewn into whatever configuration we like, and much less expensive.

Feb 3, 2020 at 11:52 pm #3629771between the dyneema fibers there is nothing but mylar that is more fragile than saran wrap.

Ouch!When DCF has been squeezed into a stuff sack a number of times, it tends to develop pinholes at the complex folds. This means the resale value of a DCF tarp or tent falls precipitously after a couple of uses.

Cheers

Feb 4, 2020 at 9:40 am #3629799“… between the dyneema fibers there is nothing but mylar that is more fragile than saran wrap.”

“Mylar” is a trade name for a version of polyethylene terephthalatem- the type 1 plastic used in the ubiquitous and nearly indestructible one liter bottles. So the material itself has merit.

DCF has many configurations, some (.75 ounce) are very resistant to puncturing, and some versions (.34 ounce) are indeed fragile. All seem to eventually “pin-hole” from creasing and abrasion.

Pick the configuration that suits your priorities.

Feb 6, 2020 at 12:12 am #3630068Greg,

I’m not one to use a 26 letter phrase, or an acronym, when a five letter word in common use will do.

Granted, I’ve not looked at DCF since Dyneems took over manufacture, but understand that it has gotten better than the stuff made by Cubic Technologies. I’d be disappointed with TarpTent using the material if that were not the case.

However, Richard Nisley has posted on BPL about numerous tests of it, beginning with Cuben in his “dirty little secret” thread. All of the available materials below .8 osy and suitable for tent canopies have had a suffix of .08, which I believe refers to the weight of the mylar. The .o8 suffix is the same whether the DCF is .35 oz, .5 oz, or .75 oz. The mylar on the selvage, or edge of a fabric roll, protrudes from the borders of the fabric and unlike the fabric, is not laminated over the dyneema fibers. It is very fragile, so much so that lab tests are not needed to see its inferiority to saran wrap or the like.

Your statement that the .75 osy DCF is very resistant to punctures may reflect improvements to the material, but I’d be interested in lab tests that show this. I’ve expressed this interest a number of times on BPL, and my curiosity has not been answered. In the meantime, I can’t buy the idea that an extremely fragile sandwich is going to make the unwoven dyneema fiber filling any more puncture resistant. Granted, I’m not talking about puncture with a hunting knife, but separation of the unwoven fibers when stuck with a pin is another matter. A few pin size holes in a tent wall will admit a good bit of water in a heavy downpour. Roger’s observation that he finds pin holes wherever the fabric is folded raises more concerns, unless he is talking about Cubic Tech’s Cuben, not the current DCF, although it appears Dyneema is still using the same suffixes. And there have been a number of reports on BPL of leaky DCF tents after a fair but not unreasonable amount of use.

Although I think the weight of mylar in a water bottle is vastly greater than the mylar in DCF, I’d love to be persuaded that the Cubic Tech stuff has been improved, as it might make it possible for me to construct some lighter tents. For what the material costs, though, I’m looking for more than I’ve seen on BPL in the way of test data, especially where the purported strength seems somewhat counter-intuitive. And your use of the word, “eventually” raises more questions for me than it answers.

It just doesn’t seem to make a lot of sense to buy DCF from RBTR, or Extrem Textil and start testing when I’ve not the apparatus, and sil or sil/PU coated nylons out there run from .7 to 1.06 osy and have been tested on BPL to be very durable and waterproof. And they’re a heck of a lot easier to make a tent with than DCF.

Feb 6, 2020 at 1:01 am #3630073unless he is talking about Cubic Tech’s Cuben, not the current DCF, although it appears Dyneema is still using the same suffixes.

I can imagine the new company brought more capital and more marketing to the table, but as far as I know PET is PET, with few (if any) additives. What additives are used are unlikely to be used for film production.

The company may have upgraded the production process, which had been small-batch-oriented before.I agree: we do need some objective testing of the way DCF punctures.

Cheers

Feb 6, 2020 at 11:28 pm #3630207Forgive me Roger, I’m not the chemist my father was. The early threads on BPL about Cuben were explicit that the outer film was a mylar material. By ‘PET’, are you referring to the outer film, or to the Dyneema fibers inside. Thanks.

Feb 7, 2020 at 12:59 am #3630215Mylar = PET = polyester

Dyneema = ultra-high-molecular-weight polyethylene (UHMWPE)Cheers

Feb 7, 2020 at 6:02 am #3630223Well, the old cuben was definitely prone to leaking over time. If we examine the manufacturing process we find that essentially the material was made by heat pressing two layers of plastic over a central core of non-woven spectra/dyneema grid. This basically means that the plastic (mylar or PET) layers reach a high enough temp to bond with each other around the core.

OK, so a sheet laid out is great. But, that is not how we use it. We travel from place to place, meaning it is rolled up/folded then unrolled/unfolded, hence the use problem. Since they are two different plastics and they do NOT bond with each other, you end up with a series of loose strings buried in plastic. Anyone who has attempted to sew a rip in DCF will tell you how pointless this is (holes enlarge and dyneema strings pull loose.)

Folding/rolling induces internal stresses on the Dyneema/mylar bonds:

Worse, the stylized drawings above do not describe the second layer of dyneema going in the second direction which simply slips easily against other dyneema.

The result of all this internal movement (discounting expansion due to humidity, heat and pressure) is tiny bubbles that eventually simply crack open due to use. Many have noted that older cuben/dcf seems to have water trapped inside the layers. Hydraulic pressure only makes things worse, but I don’t want to complicate things needlessly. Anyway, this limits the durability of DCF by the very manufacturing processes that also make it great for use.

You can also see it should never be packed tightly, meaning it will have a much greater bulk for the weight savings…0.08cuben would roughly be equivalent 1.9oz/yd nylon. (Lighter versions of nylon pack much tighter.) ‘Corse a lot of this is simply due to the bulkiness of the dyneema…don’t forget it floats!

A pretty well defined trade off in weight and increased pack volume for 5 years or durability and decreased pack volume for15 years. One of those cases where smaller is not lighter.

Anyway, the large pack volume of DCF/cuben is a detriment to an UL hiker where every ci matters.

The precision engineering needed for cutting and joining DCF into a free-standing tent means that cost will add to the already high cost of the DCF material. There is little to no leeway in the fabric. In addition to a pole architecture to supply a basic tension to the fabric, this makes DCF freestanding tents a very niche market. And, not really for the SUL/UL hiker, typically the domain of dual purpose gear like treking pole tents that are decidedly NOT freestanding.

Feb 9, 2020 at 10:00 pm #3630649Roger, thanks for responding. The first I heard of mylar, was when Jack Stephenson tried to bond it to his nylon tents to cut down on condensation. It was a clear or silvered material, like the covering of a clear cigarette wrapper, and nothing I’d identify with the woven polyester in clothing.

James, that is very helpful. But was hoping someone would explain why my doubts were unfounded. You have only reinforced them. But thanks for the additional insights.

I think the key to all this is to design a domish tent that when pitched will stretch nylon more on the bias, or diagonally across the weave, so that its sagging will be greatly reduced when wet. And perhaps with 6,6 nylon from Dupont or the equivalent, that will be even more durable, and in the 7-20 denier range. Then we can forget about DCF and polyester, and carry super lightweight nylon domes that are very durable, very strong, and cost about half as much to make or to buy.

There are just a few reservations. Why does 6-7K HH water resistant nylon, impregnated with silicone covering both sides, expand and wrinkle when dampened? It’s not the temp, as I have nylon samples, tightly stretched, that stay taut outside all winter, through freezes and thaws, as long as they don’t get wet, or even exposed to humidity. But despite their high water resistance under high pressure, when it rains or humidity rises, moisture apparently gets into the nylon fibers and they expand. Is the moisture coming through in vapor form? Maybe someone more schooled in these matters can explain.

Feb 10, 2020 at 1:31 am #3630659The silicone coating IS porous to water. I can SEE the water getting into the threads under pressure in my HH tester. This is a known problem.

Yes, cold wet nylon does stretch. Known physical property of nylon.

Cheers

Feb 10, 2020 at 9:33 am #3630692Any experiences with the ZPacks Duplex Flex (with tent- instead of trekking) poles?:

http://www.zpacks.com/shelter/duplex-flex.shtmlDoes look quite unstable for me on the picture, but could be an interesting option for those who are not using trekking poles (like me f.e. …).

That seems similar to the TarptTent Rainbow (at least in functionality). With a few extra poles, you can covert a non-freestanding tent to a freestanding one. There is certainly value in that (for reasons mentioned earlier). It is easier to pick up and move a freestanding tent, etc.

That setup weighs ten ounces, which is a lot. There are much better options if you want a non-freestanding tent, but don’t carry poles. Simply buy a set of poles for your tent. It is quite likely that the tent poles will still be considerably lighter weight than the poles used for a typical freestanding tent. For example, a pair of lightweight poles typically weigh less than four ounces (two ounces a piece). I sometimes carry one for my Refuge X if I’m doing some base camping (i. e. a few day hikes without moving the tent). The tent can stay up with one of the poles, which means the tent doesn’t flop around during the day (and I don’t have to worry about water getting in, etc.). Likewise, if I’m doing exclusively base camping (e. g. setting up camp only once) than I’ll sometimes carry two poles, just so I don’t have to bother with adjusting my trekking poles. The poles are not as strong as trekking poles, but as strong as most freestanding pole setups.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.