Topic

Starlyte XL Initial Impressions and testing

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Gear (General) › Starlyte XL Initial Impressions and testing

- This topic has 22 replies, 9 voices, and was last updated 7 years, 6 months ago by

DAN-Y.

DAN-Y.

-

AuthorPosts

-

Mar 17, 2015 at 8:19 pm #1326952

Ok….40 test boils later, I have my initial results using the new XL starlyte burners with my .9 evernew ti-tri sidewinder setup.

In a nutshell: Same great efficiency as the original starlyte, but in a larger storage size.

For testing, I'm in Boise, at 2600', with an air temperature of 68* (inside my house). Using Kleen strip green (90/10 mixture). Boiling 500ML (grams) of 32* water (ice bath water…probably closer to 34*), to a rolling boil.

With the nonmodified starlyte xl, I would get a boil with 12g of fuel, and 10:35 boil times. According to the Stove efficiency excel spreadsheet, that is 61% efficiency.

With a modified starlyte, I still averaged the same amount of fuel, so the same efficiency…just longer boil times (slightly above 14 minutes).

In the same configuration, the original starlyte used the same amount of fuel, and boiled on average at 10:25.

I did not have much soot on the bottom of the pot with any of the starlytes.

So, its definitely efficient…its nice getting a rolling boil from ice bath water to rolling in .8 of a tablespoon of fuel.

As for the stove itself, I was able to put exactly 96 grams of fuel in the stove. The storage is crazy….with 96g I can hold it upside down, leave it on its side for 15 minutes, etc and it won't drip. But, if I put in 1g more…then it will spill that 1g.

The original starlyte holds about 30.5 grams of fuel, for a total weight of 43.5 (starlyte weighs 13g). The starlyte xl weighs 29g with lid, and holds 96g of fuel. So, for 17g you can hold an additional 65.5g of fuel. Not only that…but you don't have to keep filling your stove up…just do it once and forget it.

Only downside that I have for the starlyte XL is the size….now it doesn't fit inside my pot and sidewinder setup. But if you used a different setup, like a fusion/fissure cone, then you would have plenty of space in the middle for stove storage.

The stove also came with a green silicone circle that could be used to snuff out the flame and make sure that you do not lose fuel after a burn while it cools. Nice idea. I will mention that as a test, I left the burner with only the silicone cover on and it eventually did lose about 1g every 12 hours of fuel to evaporation. Either the fuel was escaping b/c it wasn't a air tight solution or the silicone itself was air permeable. However, if I just put the normal plastic cap on the stove, …no fuel evaporated.

Dan also included a round piece of carbon felt, with a circle cut out of it. You could bring the whole thing (2g) or just the outer ring (1g). If you have the whole thing, you could use it to snuff out the stove by tossing the felt on top. Though, I never have an issue with blowing the stove out. Well, blowing isn't the right word, more of a large "puff" of air will do it. If you have the outer ring, and a nonmodded XL, then you can just throw the ring on top and voila….modded starlyte (the hole is the same size as the modded starlyte size). Its my recommendation to just get a normal starlyte, nonmodded.

Oh….and one other difference between the starlyte and starlyte XL. When trying to do only 1 burn on an empty stove…with both stoves you can't put in the exact amount of fuel that you normally need (12g in this particular case). With the original starlyte, I would need to add 2g or so in order to ensure a boil. But with the larger starlyte XL, I would need to have 4 extra grams of fuel. I don't "lose" that fuel though. If I add 16g of fuel, I would get a good burn and still have 4g of fuel left. But if I put in 14g of fuel, it wouldn't get a rolling boil (flame gets too weak with <4g of fuel in the stove.)

Mar 17, 2015 at 10:04 pm #2183632I've also done a bit of testing with the Starlyte XL, Starlyte XL Restricted and regular Starlyte. I tested these stoves with two pots: a tall-narrow 0.75L Evernew and a wide-short 1.3L Evernew pot.

I distilled the results into two metrics: efficiency and power. Efficiency is the % of energy from the fuel that made it into the water, while power is the rate of energy delivered into the water (megajoules per minute). So efficiency is a proxy for fuel efficiency while power is a proxy for boil times. These metrics are nice because they allow anyone to compare their results even if using difference fuels, volumes or start/end temperatures. I won't go on about the specific test conditions here unless someone asks.

It is worth noting that these results do not have the replication I would like. The excellent working space I had (concrete bench + top notch lab equipment) is now occupied with expensive new equipment so I was only able to conduct a single test for each stove-pot combination. I think the results are pretty good as the conditions were highly controlled with top notch equipment, but I wouldn't read too much into the smaller differences.

Results

My results generally agree with John's that the regular Starlyte and the Starlyte XL have similar overall efficiency. However, my results also indicate that efficiency is influenced by pot shape (or cone shape) such that there can be a difference for specific pots. My results find higher efficiency for the restricted Starlyte XL as expected.

In terms of power, the Starlyte XL consistently lags the original Starlyte by 15% for both pots, while the restricted Starlyte XL was an additional 15-20% slower still, or overall 30% slower than the original Starlyte. All stoves consistently operated at higher power under the larger 1.3L pot.

Discussion

The Starlyte XL had lower efficiency (50%) in the small 0.75 Evernew cone than the regular Starlyte (55%). I suspect this is because the physically large stove occupies a substantial portion of the cone's volume and possibly impairs airflow through the bottom vents as the cone diameter isn't much larger than the stove diameter. The restricted Starlyte XL did the best of all (57%), perhaps because it's lower demand for oxygen meant that it wasn't impaired by some blockage of the bottom vents, but it could also be that the centralized flame lost less heat around the sides of the pot.The efficiency results are opposite for the larger 1.3L cone, which is the lone seemingly inexplicable result from my testing. The Starlyte XL faired better than the regular Starlyte (57% vs 50%) although the reasons for this are tougher to speculate. Possible explanations include experimental error, cone airflow dynamics and stove temperature (stoves burn faster in the larger cone and maybe the small Starlyte stove was overheating?). I have observed difficult to predict stove differences in different cones in the past (original Starlyte wins in 0.75L but burns inefficiency in Zelph's 0.9L fire pot where a restricted stove wins) so performance seems to be influenced by cone dynamics that aren't well understood.

The "power" results are cleaner and look really nice. Across the board, the larger 1.3L pot heated water faster. This could be the result of the larger bottom surface capturing a larger portion of the energy (vs. escaping) but then we'd expect universally higher efficiency for the 1.3L pot which isn't true. A better explanation is that the larger cone provides a greater oxygen supply, allowing for a faster, hotter burn and thus higher 'power'.

It's not surprising that the restricted Starlyte XL is the slowest stove, but it was interesting that the non-restricted Starlyte XL was consistently slower than original Starlyte. My hypothesis for this is that the larger mass of the Starlyte XL (I tested the stoves 2/3rds full) means that it takes longer for the stove to heat up to full operating speed. A hot stove vaporizes the fuel quicker and thus burns hotter/faster, so the original Starlyte likely heats up quicker and thus has faster burn times.

Conclusions

The XL design probably does slow down boils by ~15% because the larger mass takes longer to heat up. This would be more pronounced for a full XL than a near empty one. It is capable of similar efficiency as the original Starlyte, but this can vary depending on the cone shape.The restricted Starlyte XL offers outstanding efficiency around 60%, but with that comes lower power. The low power is particularly true for small pots. Hikers should carefully weigh the efficiency-power trade-off when choosing a stove. It took 13 minutes in the lab for a restricted Starlyte XL to raise 500mL of water from 20C to 99C. If you're using a small pot, boiling colder water or boiling larger volumes the restricted stove may be a poor choice despite the fuel savings.

Mar 17, 2015 at 10:29 pm #2183636"According to the Stove efficiency excel spreadsheet, that is 61% efficiency.

It seems like you're getting great results. The wide bottom 0.9L pot is likely a great setup. Your higher results could also be occurring from a lower starting temperature (I used 70F) because heating is more efficient at lower water temperatures as heat isn't being lost to the room as quickly) or because I used a thick concrete surface for my testing which can absorb a lot of heat.Boiling is also a little more efficient if you start with a hot stove rather than a room temperature one, not really because of the stored heat, but because a cold stove burns slower for the first couple minutes where it burns more cleanly and efficiently (i.e. similar to a restricted stove).

Mar 17, 2015 at 10:46 pm #2183639Thank you Dan for your input. I wish I had better lab equipment….my scale only does to the nearest gram, though sometimes it would fluctuate between two gram measurements (like 8 to 9) so I could sometimes get a .5 measurement (8.5).

I used the ice water bath….solely b/c it gave me a near accurate temperature starting point. No thermometer needed. (though I do have a kitchen thermometer and confirmed the temperature).

The big regret that I have in my testing…is the inconsistent "stopping" points that I did. I stopped at rolling boil, but sometimes I might have considered a rolling boil differently between boils. I wish I had a good temperature probe instead….especially since I hated lifting the pot lid off several times to check boiling, which lost efficiency.

I will say though….I thought it was very important in my own testing to do lots of different test boils, since it would vary quite a bit. For example, between 11g – 13g for a boil, and boil times could be off by a full minute from each other.

Am I correct in that you said you did 1 test only per configuration?

Mar 18, 2015 at 5:06 am #2183655Doing 40 boils tends to smooth out rough data measurements to the point that you can at least say "A is better than B".

But yes, a good thermometer with a probe is nice for picking a consistent stopping point, which for me is normally about 195°F (I live about 100 ft ASL), at which point there are quite a lot of bubbles. Using actual boiling temperature is not very good because water must achieve a rolling boil and maintain it for 15-20 seconds before the thermometer will read 212°F (or about 207°F in your case). I guess it takes a while for the bubbles and convection currents to thoroughly mix the mass of water.

Mar 18, 2015 at 5:13 am #2183656Great information so far. Quick question… Where lives this stove efficiency spreadsheet of which you speak?

Mar 18, 2015 at 8:27 am #2183701You can find the spreadsheet here ->

Mar 18, 2015 at 9:08 am #2183731"I thought it was very important…to do lots of different test boils….Am I correct in that you said you did 1 test only per configuration?"

Yes, I only did 1 test per configuration and yes it is important to do many boils. I was holding off on posting my results because of the lack of replication, but it became clear to me that I couldn't resume testing in the lab, so these results should be taken with the appropriate caveats.

In the past I have done quite a bit of stove testing, so I have learned many of the common pitfalls that add variance to the results. These include (1) using a cool vs. warmed up stove, (2) operating the stove with varying fuel loads and (3) operating the stove repeatedly on the same surface, which gradually gets hotter over time. All of these were controlled in these tests. I also used a scale that measured to 0.001 grams and a thermometer to 0.1 degrees

I also took steps to avoid variance from a vague end point. By using "efficiency" and "power" rather than absolute measures (fuel used or time to a boil), I didn't need to bring the stoves to a consistent end point. I heated the water very close to a boil and recorded the actual finishing temperature along with the fuel used. This gives me the total degrees gained, which is then used to calculate efficiency and power. So replication is absolutely important, but my results are likely less variable than your typical DIY results. The consistent differences shown in my "power" figure also suggest to me that these results are pretty accurate.

On another topic, a better explanation for the consistent differences in "power" between the 0.75 and 1.3 pot is that the 1.3L pot sits higher off the ground (60mm) than the 0.75L pot (49mm). This creates a larger gap between the stove and pot, which lets the stove burn faster but less efficiently, as my previous trials with varying the gap on my 0.75L pot have shown (see below).

Also worth noting, my original Starlyte is shorter (22mm) than the Starlyte XL (26mm), so I shimmed the original Starlyte up 4mm so that the stoves were comparable. The actual stove-pot gaps were 34mm (1.3L) and 23mm (0.75L). I'd be interested to hear the gap for your 0.9L setup.

Mar 18, 2015 at 2:16 pm #2183849Ok, the cone is 4 13/16" tall, and the bottom of the pot to the lip is 2.5". I'm measuring a starlyte XL as 15/16" (from the lip to the bottom …so where the flame is).

So, that is 4.8125 – 2.5 – .9375 = 1.375"….which is 34.925 MM gap.

Mar 18, 2015 at 4:35 pm #2183916Cool. Very similar to my 1.3L

Mar 18, 2015 at 4:51 pm #2183921Well done guys.

This is seriously tempting me towards getting a restricted starlyte XL. Not having to open a fuel bottle and refill as often will reduce all the little micro spillages that go with that procedure; reducing risk and improving efficiency.

Cheers!

Mar 19, 2015 at 2:08 pm #2184181I forgot to ask…how does a starlyte XL fit into a 1.3L evernew with a sidewinder cone in it? Is it possible?

Mar 19, 2015 at 3:49 pm #2184223My 1.3L Evernew pot has the frying pan lid so it fits easily. I'll have a look to estimate if it'll fit with a regular lid when I'm back home in a few days. It might work standing on it's side beside the cone if the diameter of the stove is less than the height of the pot.

Mar 21, 2015 at 7:51 pm #2184841Wow, great test results. I'm glad the burner tested well. The test are really well done, thank you. Charts are scientific…kudos!!

I'm going to make available on Monday the XL-Small which is comparable to the Modified StarLyte in the size of opening.

The stove will consist of the Burner, stainless steel pot support and the plastic lid to prevent vaporization of remaining fuel. Also will include the silicone snuffer/fuel retention disc.

Jun 26, 2015 at 7:12 am #2210205Jun 26, 2015 at 8:45 am #2210223Brilliant info. Thanks all.

Jun 26, 2015 at 9:32 am #2210239Thanks, Robert! Here is more info on the testing and a link to bplite.com where there is more information in a thread.

Here are some quotes from my website bplite.co

http://www.bplite.com/viewtopic.php?f=2&t=6290skuzapo » Fri Jan 23, 2015 1:13 pm

Here are some prelim test pics and results from the "Prototype" These were done in my workshop at ambient of 65 degrees. I am using a evernew titanium 750ml pasta pot with 2 cups of water at 65 degrees for all tests.First Test is with the burner filled with 4 oz, rested for an hour. Note this did take 14 Min to get to 212 deg, this is the first test and there was 4 oz of denatured to warm up.

So now the thought is to check with a windscreen although not much draft in workshop. This is an aluminum one with stakes as a pot support that will hold the pot, same evernew, 1 inch above the pot. oops changing 2 variables. Point here is to see if the windscreen creates greater temp over more surface. This test i get 11:49 min

So next I go to look at the height of the potstand and run a test with a 1 inch gap between burner and pot but no wind screen. This test i get 12:31 min

So the initial observation confirms what Zelph found, reduce the height of the poststand to get to approx 1 inch. I am not sure if the windscreen helped much on the bench, i am sure it is a necessity outside

I ran the prototype with the 1.5 inch SS for 7 consecutive burns, the 7th ran out of fuel at 203 degrees, close. Damn efficient! So I would bet that you could estimate 4-6 boils with 4 oz of denatured outside under summer conditions with a windscreen. I did a run using the standard starlight and boil times improved by approx. 1.45 min, bench results

So I concur with the suggestion to reduce potstand height and open the burner port size

Hey this was my first post, followed the instructions and it worked. Nice burner/stove

Cheers, Skuz

skuzapo » Fri Jan 23, 2015 7:02 pm

Zelph, the construction is great. I don't know how you get that top clamped on so neatly. There are no leaks whatsoever. I had that baby turned upside down a whole night and not a drip with 4 oz in suspension. I like the strength that this rolled or clapped rim gives the burner, like your Fosters pots. The ridge at the bottom of the pot and the ones underneath give the bottom strength , this will keep it from getting too beat up in a pack or pot. It sure is lightweight and yet ridge for aluminum . Its amazing what folds and ridges can doSkuz

Jun 26, 2015 at 3:03 pm #2210324Dan Goggins,

Yes, the Starlyte XL fits into the 1.3 Evernew pot with the regular lid, along with the sidewinder cone. Note that in the following pics I've even got the inferno grate in the bottom of the pot:

Jun 27, 2015 at 9:46 am #2210467

Jun 27, 2015 at 9:46 am #2210467Rob, everything fits nice. How is the XL working out under the cone? Any evidence of a radical burn?

Jun 27, 2015 at 5:54 pm #2210568The XL is "evolving"

Jun 29, 2015 at 1:22 pm #2210959Dan,

I haven't had a chance to try it out yet…I just placed it into the pot to make sure it would fit. I hope to be able to try it out next weekend, hopefully.

Aug 12, 2015 at 5:38 pm #2220719This is the new addition to the StarLyte series. It was specifically designed to be used in the Western United States where burn bans are in effect during drought conditions. Federal and State laws require stoves to have shut-off valves during high risk fire conditions. This stove meets the rigid requirements of Cal Fire in the State of California where there so many wild fires existing as of this date. Once the stove is filled with fuel, it will not spill out just as we see when jelled alcohol is used. Laws refer to jelled petroleum as being legal in backpacking stoves.

Jul 28, 2017 at 11:17 am #3481563

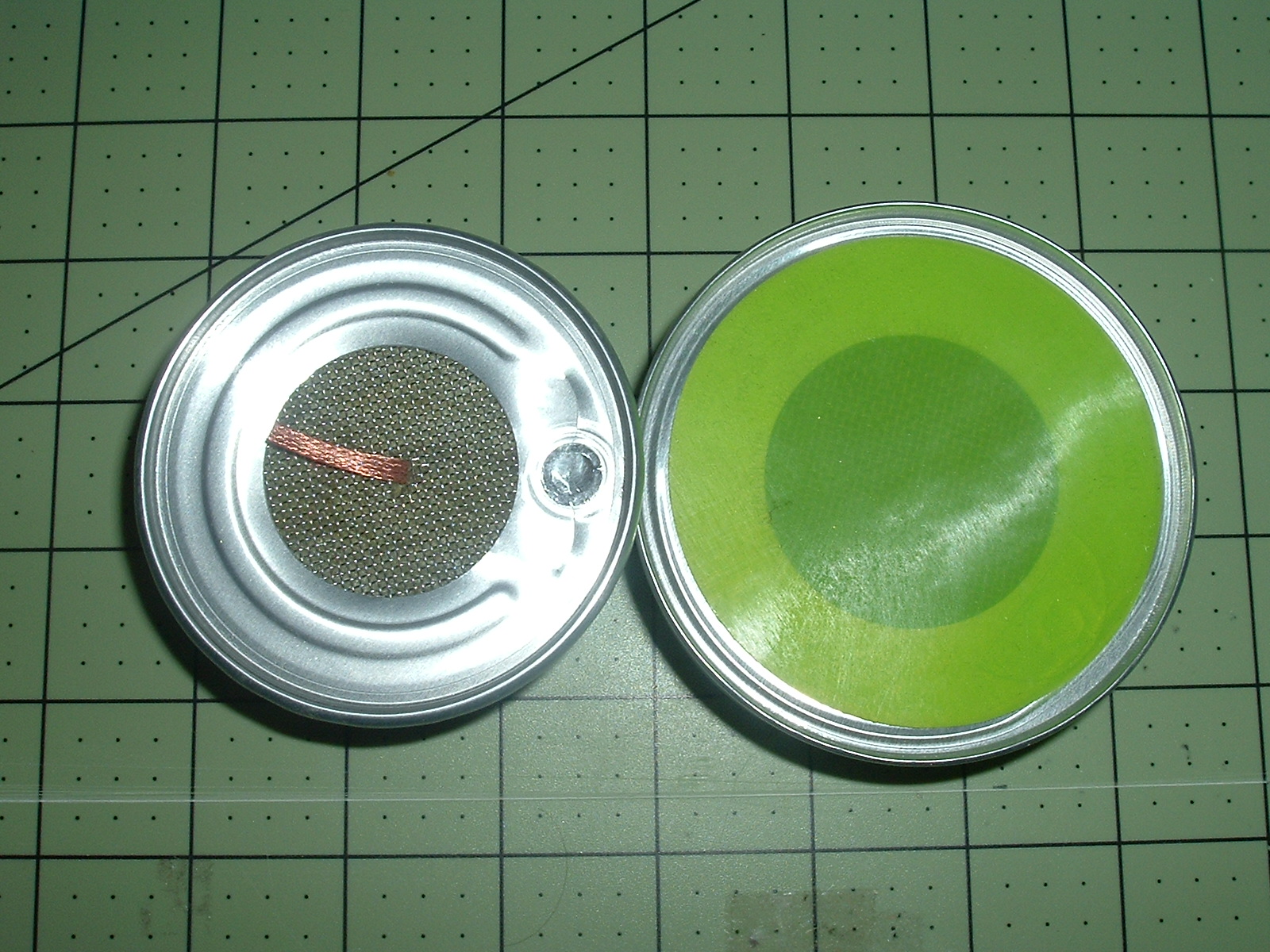

Jul 28, 2017 at 11:17 am #3481563The Starlyte has evolved to a 3″ diameter burner, pictured on the left. The green silicone disc on the larger burner is used to snuff out flame and prevent vaporization of fuel while cooling down.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

HAPPENING RIGHT NOW (February 11-21, 2025) - Shop Hyperlite Mountain Gear's Biggest Sale of the Year:

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.