Topic

1.1 to 1.4 oz sil\pu options for MYOG pyramid tent

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › 1.1 to 1.4 oz sil\pu options for MYOG pyramid tent

- This topic has 15 replies, 7 voices, and was last updated 8 years, 5 months ago by

Sam Farrington.

Sam Farrington.

-

AuthorPosts

-

Jul 2, 2016 at 11:12 am #3411930

I have been a cuben user for the past years but my enthusiasm had been dampened by its lack of longevity (See Jennifer Mitol posting re cuben degradation, which I have also experienced myself). So looking to make a new pyramid and wondering people’s first choices of material for tents they have made.

Thanks

Derrick

Jul 2, 2016 at 4:08 pm #3411958I use regular 1.1oz silnylon. After everything is cut out and assembled, I coat everything with calk and mineral spirits. This makes things somewhat heavier (around .2oz/yd) but makes things quite durable and totally waterproof. Cuben, as you say, has limited durability.It has about 60% of the weight of nylon, but only around a 5 year durability with occasional use…if you use it a lot, 2 years.

The newer membrane is almost too light for any more than 2 person sizes. And, it requires a certain amount of reinforcements. By the time you add it all up, it is almost the same as just using the 1.1oz fabric for smaller two man tarps.And it is too light for the larger panels required for 3 or more person tents.

Poly fabrics are far less strong than nylon. The only problem with Nylon is it stretches when it gets wet. A fair price to pay for the additional strength in my book.

Jul 4, 2016 at 10:54 am #3412175Thanks James. Very helpful.

Jul 7, 2016 at 6:26 am #3412831Trying to post a reply here but it isn’t work and does work in the test forum so posting this as a quick test.

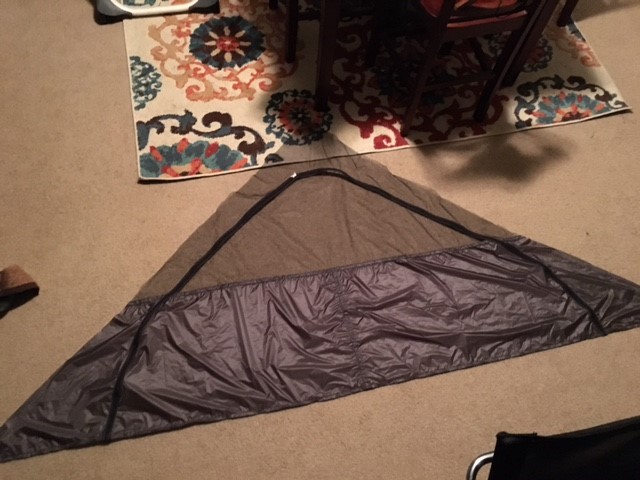

Jul 7, 2016 at 6:27 am #3412832<p style=”line-height: 18.9pt; margin: 0in 0in .2in 0in;”><span style=”font-size: 10.5pt; font-family: ‘Arial’,sans-serif; color: #333333;”>After a learning experience the Membrane Silpoly I actually trust it very much. The key seems to be to glue the reinforcements using the same membrane and nothing heavier. I’m actually in the middle of building a membrane version of a cricket/hexamid style shelter and it’s going very well. I’m only using glued membrane for the reinforcements and I truly believe it will be plenty strong. Except mine will not use a separate inner, it will be single wall with a 1.1 Silpoly PU4000 bathtub floor and the bottom half of the door uses the new 7D Robic from RSBTR so I’ll have plenty of splash protection. Pics so far are below. I really like working with the Silpoly though.</span></p>

Jul 7, 2016 at 6:29 am #3412833

Jul 7, 2016 at 7:43 am #3412852

Jul 7, 2016 at 7:43 am #3412852I’d want to use a lighter sil nylon or poly, like Membrane 0.93 oz/yd2 finished weight silpoly.

1.1 oz/yd2 sil is maybe 1/4 oz/yd2 finished weight so the finished tent will be 50% heavier. I’ve used this for years without problem, but it is a bit heavier.

just silicone is better than if you include PU, because it’s stronger, and you don’t need the extra waterproofness that PU gives. Pyramid walls are steep so it’s not so important to have the best waterproofness. PU would be good for a floor where you need more waterproofness.

I agree with James – nylon stronger, so I’d prefer silnylon, especially for the lowest weight. Yeah, it stretches a little when wet, so I just have to tighten the guylines or raise the pole a little.

I’ve never sealed my seams or the body of the fabric even though I have cheap silnylon and used it for years. Yeah, I can occasionally feel a little misting, but it’s not enough to get my stuff wet. They get much more wet from condensation. You could try it out and see if it mists too much before sealing it and adding the extra weight.

Jul 11, 2016 at 11:58 am #3413645Hoosier and Jerry, thanks for your replies. I assume you are both referring to Ripstop by the Roll membrane? I note that their .09 Membrane SilPoly (without the PU 4000) will accept Silnet sealer. This confuses me a bit. Can I assume the following:

- Silpoly is a combination of both silicone and pu and wonder?

- Despite the presence of PU, it will accept SilNet or silicone based adhesives and sealants?

- The RBTR Membrane .9 PU4000, is the same membrane but with an extra pu coating insider?

- Jerry would prefer silnylon to any version of the membrane material and the presence of pu is less strong?

Thanks

Derrick

Jul 11, 2016 at 12:16 pm #3413648- I assume you are both referring to Ripstop by the Roll membrane? You are correct. I’m using the Membrane Silpoly without the PU coating.

- Silpoly is a combination of both silicone and pu and wonder?This is how it’s described but silicone adhesives do bond extremely well.

- Despite the presence of PU, it will accept SilNet or silicone based adhesives and sealants?Yes it will and very well. On my tarp I used Permetex flowable silicone. For this latest project, I’m using GE Silicone II houseglue glue. It bonds so well that I’m certain no stitching will be required on my tie outs. The reinforcements will only be glued since the stitching is what contributes to the stitch elongation. No stitching = no elongation. :)

- The RBTR Membrane .9 PU4000, is the same membrane but with an extra pu coating insider?Yes, just on the inside. This material is not the best material to be used for tarps since the PU coating makes an already fragile material even weaker. Although, some have without issues. The 1500 mm HH rating of the standard Membrane Silpoly was just fine for me during the short time I used the tarp and it did see some heavy rain so I see no benefit to using the PU4000 for the canopy.

FWIW, when bonding tie outs using the same material, the Membrane is seriously awesome. After adding the bonded reinforcements on my tarp, I tried to tear it just to instill some trust in the material. No dice…the panels themselves are rock solid and I have zero concerns working with it. You just have to use the proper technique for the tie outs. The aforementioned tent is nearly finished (minus the floor) and I have done the same with it’s tie outs and they’re solid. I will be posting a thread when it’s complete.

Jul 16, 2016 at 2:46 pm #3414596There seems to be on these forums quite a difference of opinion about the strength of RBTR membrane polyester vs nylons of similar weight. No sag with the polyester, but it might not be able to survive tempests above timber line. Not necessarily a problem with the reinforced tie-outs, but with the fabric wall of the tent overall.

The membrane is coated on one side with a PU coat that bonds very strongly to itself with thinned Seam Grip, but on the other side there is a silcoat that bonds only to sil glues. Have never been fully satisfied with the sil glues and sealers for bonding, despite the classic article on this site. Not a problem with membrane, because of the strength of the bonds using only the PU coated sides of the fabric.

StoS has a similar weight NYLON fabric for its Escapist tarps that they state is coated with a sil and PU combination on both sides, but it does not bond well with sil glue or sealers, IMO. Will try the Seam Grip, and think that might achieve the same solid bond as the PU side did on the membrane. Needless to say, buying a tarp to salvage the material is much more expensive that buying membrane or other fabric as yard goods.

Of course the nylon, even with the newer coating, does sag a little, but nothing like the old silnylon. Again, just how strong the nylon is with the new sil/PU coats is a mystery. But it is surely stronger than polyester of the same weight, whatever the coating.

It should be noted that when nylon sags on the upper section of a canopy, the potential for leakage due to the pounding of heavy rain on the bowl-shape created by the sag, is much greater. This has been illustrated in shower tests posted on this site with You-Tube links.

Roger posted about the newer TPU coatings a while back, but can’t locate it.

Would like to resolve all this before the next tent. As suggested by a post above, it might be just a matter of using a heavier fabric, and/or a heavier coating, but that kind of defeats the mission of trying to switch to lighter tent fabrics.

Jul 20, 2016 at 4:18 am #3415177I read “polyester is stronger than nylon”, and had to do some homework, as the last mid I built was out of 1.1 silpoly, which did not do so great in high winds (lots of stretching in the sidewalls, despite 16 anchor points, and 8 guy lines). And I found these two nice comparisons from the pros:

http://nemoadventureanywhere.blogspot.se/2009/11/nemo-classroom-lessons-164-nylon-vs.html

http://thetentlab.com/MoonLightTents/PolyNyl.html

bonus video of my 1.1oz silpoly shelter in norway getting hammered (it did not leak, or break, though). notice the stretching between guy line attachment points. better pitching (lower to the ground?) probably would have helped, as well as a more protected spot, but those were unavailable… this trip made me re-evaluate mids, as I think a tipi (more sides, less flat faces for wind to collect on), would have fared better. also, maybe a little more cat curve could have helped this shelter out… this used 1.5″ over something like 100″ edges.

Enjoy!

Sep 10, 2016 at 11:18 pm #3425462Some further thoughts about your questions about fabrics:

It has been about a year since Richard Nisley’s tests of several of the RSBTR polyester fabrics were reported on this forum.

At that time, some of them were designated to have “PU2000” coatings, and those no longer appear on the RSBTR site. So it is not clear whether the Membrane PU 2000 that Richard tested at over 3000 mm HH is the same material being offered today.

The other 2 polyesters Richard tested, a coated Membrane without the PU 2000 designation, and a 1.1 oz (1.21 oz with coatings) polyester, tested poorly after artificial aging, both around 492mm HH, less than a third of the industry standard, and even less than the standards espoused by Roger Caffin, the forum editor.Unfortunately, since RSBTR lists the membrane as 1500mm HH, I fear it may be the Membrane that tested poorly, but you won’t know it until the tent has been shedding water for several weeks, which Richard’s tests are intended to simulate.

For this reason, as desirable as a polyester canopy may be because it does not sag, a nylon material with a sil/PU coating may be preferable. However, for that the tent design should enable tightening of the tension on the tent walls. For an A-frame design, this could be just a matter of reinforced pullouts on the side walls of the tent. Check out: https://backpackinglight.com/forums/topic/103756/ for ideas.

For the floor, the 1.1 oz (1.4 oz with coatings) RSBTR polyester with the PU 4000 coating may work well as others suggest. Worth trying, based on the favorable reports on this and other threads. A gossamer fabric that might be super for the canopy, might tend to bunch up on the floor a be a nuisance.

Happy trails and tent making.

Sep 11, 2016 at 12:23 am #3425471In regards to the RSBTR poly fabrics, I’ve come to the conclusion that the non-PU versions are strong enough for a mid. I have a mid made with the 1.25 oz (finished weight) silpoly and it held up well to some pretty strong driving rain and winds this summer above treeline in Colorado. Better than my previous mid made of cheap eBay silnylon. That was after about 20-30 nights of use prior to that trip. I’d say at this point it’s had about 50 nights total.

I think the 1.4oz PU-coated poly is probably sufficiently strong for a ‘mid as well, but I would rather have the piece of mind of a little extra strength. If it starts to mist after more use that won’t be a major issue for me.

The no-sag is one of the reasons I like it, but another advantage of polyester is that it doesn’t absorb as much water. A silnylon mid will take on quite a bit of water weight after a night of rain, but with the poly mid I can shake it pretty dry before packing it up.

Sep 14, 2016 at 6:46 am #3426094Probably should have also posted the link to Richard Nisley’s tests referred to above:

https://backpackinglight.com/forums/topic/98106/page/2/#comments

Scroll down to his posts dated October 6th.Note that the RSBTR coated polyester of 1.24 or 1.25 oz finished weight is the material he tested: “1.1 oz SP 2nd Gen Dark Olive Sil/PU” – PU referring to the polyurethane in the coating, and note the statement on the product page: “This fabric is coated with a silicone/PU layer on each side …. .”

Richard tested this fabric and found the aged HH of the fabric after 5,400 wet flex cycles to be 492.09 mm H2O. That is quite a drop from the spec’d HH of 1500mm, albeit the fabric coating may have survived a night or two of driving rain above timberline.

As stated earlier, agree that the RSBTR 1.4 oz polyester ripstop fabric with a coating rated “PU4000” may be much more water resistant, but so are other fabrics of that weight, such as silnylons sold by Thru-Hiker and Lightheart Gear. Compared with silnylon, the strength of the PU4000 polyester fabric, with the heavier Polyurethane coating on one side, remains a concern.

Guided by Richard’s test results, the sil/PU coated 1.1 oz mini RS nylon used in the StoS Escapist tarps, or the sil coated 1.15 oz mini RS nylon used in Terra Nova tarps, appear to offer a strong and lighter alternative with greater water resistance over time. Note: https://backpackinglight.com/forums/topic/105800/

Sep 14, 2016 at 7:49 am #3426100I think I’d use the 0.93 oz/yd2 Membrane silpoly based on people’s reports. I’ll probably do that some day because my current tent is kind of a patchwork and needs replacement.

Just make sure you reinforce corners by gluing on a triangle of the same fabric. The amount of area of reinforcements is small compared to the total area of the tent, so it doesn’t add any significant weight.

Membrane will end up saving 33% of weight compared to typical 1.4 oz/yd2 silnylon like my current tent. Maybe my mid will weigh 16 ounces vs 22 ounces – 6 ounces savings – that’s something…

Sep 16, 2016 at 10:24 pm #3426602RBTR now offers a PU 4000 Membrane Polyester at 1.07 oz finished weight per sq. yard.

The denier is 15D, which i think will be adequately strong for a tent or tarp canopy.

Possible drawbacks compared with nylon are the lack of any reinforcement (ripstop) threads, diminished strength due to the thicker PU coating, and limitation on bias stretch for the same reason.Where there must be a trade off between reinforcement threads and water resistance, posts from Editor Roger Caffin appear to lean in favor of increased water resistance. The remaining concern is whether the bias stretch will be adequate for a canopy with the desired tautness. Will order some and find out. Hope springs anew for a no-sag tent.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.