Topic

Moulder Strip put to the test. Butane canister use at -21F/-29C

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Moulder Strip put to the test. Butane canister use at -21F/-29C

- This topic has 71 replies, 22 voices, and was last updated 7 years, 1 month ago by

David Thomas.

David Thomas.

-

AuthorPosts

-

Jan 19, 2017 at 1:19 pm #3446090

But, yeah, what remote canister stove works at -20F and weighs less than 60/70 grams?

Better just add a sanity check here. If the canister is at -20 F it won’t give off any gas. So NO stove will work with any screw-thread canister at this temperature.Under these conditions your options are:

* Use a Coleman Propane canister/bottle with an adapter (Will Rietveld was doing this in some articles)

* Keep/get the canister warm beforehand so some gas will come out.Cheers

Jan 19, 2017 at 2:49 pm #3446101I should have said, “what remote canister stove works at -20F *OR* weighs less than 60-70 grams?

<i>Edited to add: </i>Bob and I are talking about ambient temperatures of -20F. And at those ambient temperatures, how can an initially-warmed canister be kept going.

Jan 19, 2017 at 2:55 pm #3446102Well clearly at -20°F any fuel short of propane will need a ‘kick-start’ to warm it up in order to use it with any stove.

What happens after that is the fun part. :^)

Jan 19, 2017 at 2:56 pm #3446103No stove works when the canister is at -20 F. End of that story.

As for the weight limit – I’m working on it! :-)Cheers

Jan 21, 2017 at 2:03 pm #3446395Made several aluminum heat “strips” using 1/8″ welding rod.The aluminum is very easy to work with. Cut it to length with wire snips, hammered it flat with no work hardening issues, easily hand-bent to curve around the canister.

The first is a simple straight piece flattened at one end for contact with the canister:

This set up reached over 200* F at the junction with the canister in about 15 seconds, so I bent the top tip away from the flame to run cooler.

Next I made an “L” shape. The aluminum is so easy to work I just bent it rather than TIG weld a flat piece to it:

Finally I made a double “L” for extreme low temperatures, and TIG welded the top tips together for ease of installation:

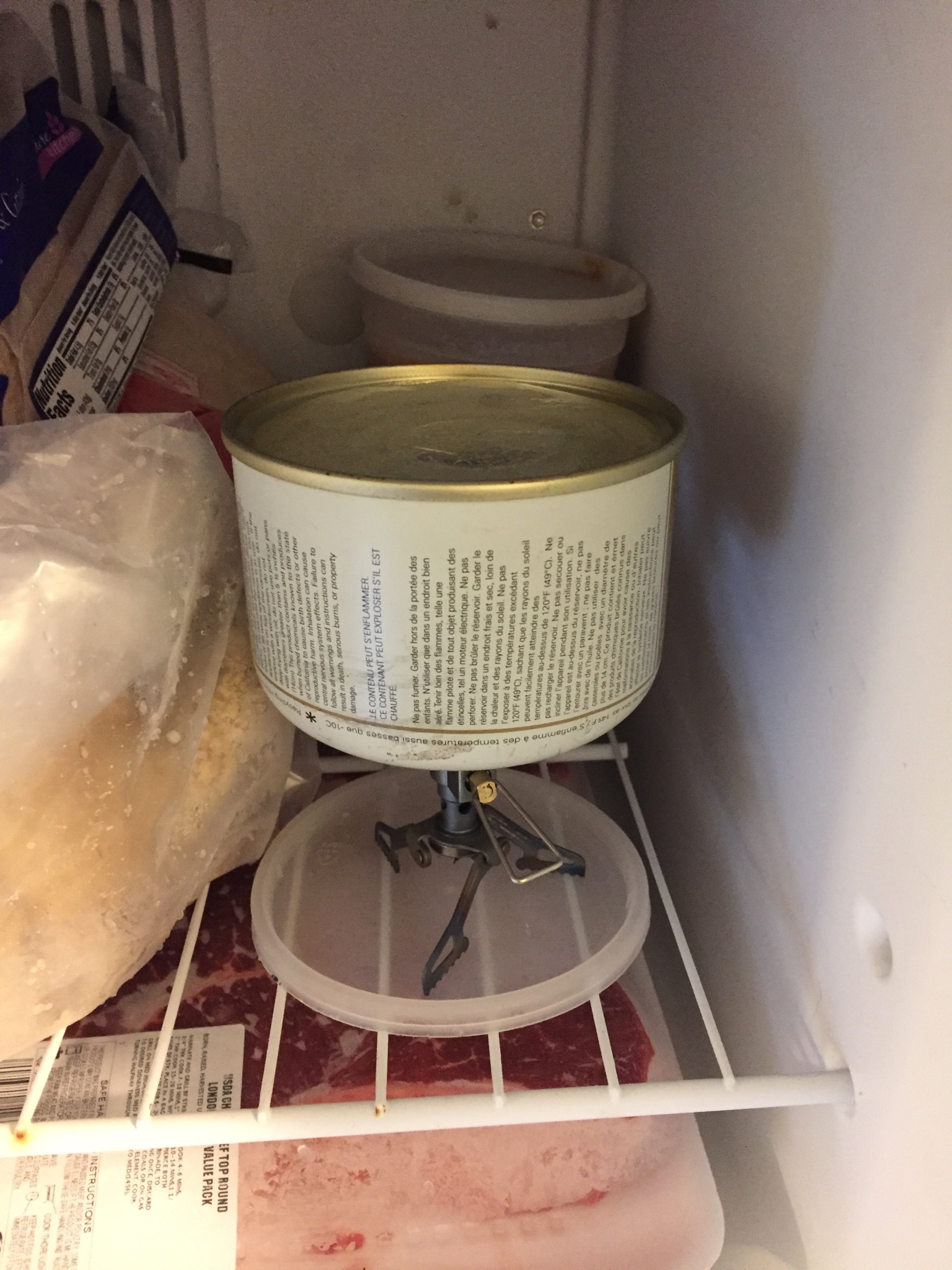

To test I put the stove in the freezer with water filling the base concavity:

Once it froze I then put the rig in a tray full of ice with about 1/8″ of water to insure good contact with the canister:

Warmed the canister for 30 seconds by putting my hands down on it and it fired right up and ran beautifully with all the various configurations. Now, if I could send the bits to David Thomas for some truly low temperature testing…

Tried TIG welding a couple of Foster’s cans together. Managed to get them joined, but embarrassingly ugly welds. No way I’m posting a picture of that mess. Whoever welded those soda cans together is a TIG-welding maestro/guru. Beautiful welds!

Jan 21, 2017 at 2:36 pm #3446400I like the way you have increased the contact area onto the canister, but whether the wire is thick enough to match a strip I am not so sure. Four wires maybe?

As for the ice water bath – that is a quite common way of warming a canister. You see, we have the following figures:

Water/ice temperature: 0 C

N-Butane boils at -0.5 C

Isobutane boils at -12 C

Propane boils at -44 C

The Snow Peak gas canister you show contains a mix of propane, isobutane and n-butane, and will probably still work at -10 C.

Colder testing needed!Cheers

Jan 21, 2017 at 2:46 pm #3446401Yeah, although the 1/8″ rod got very hot, I’m not sure it was carrying enough heat to do the job. Colder testing definitely needed! I’ll see about picking up a block of dry ice, which I think is about -110* F. Yikes! I’ll have to fiddle with some heavily salted water to see if I can get it down into the -20 range.

Or…David T?

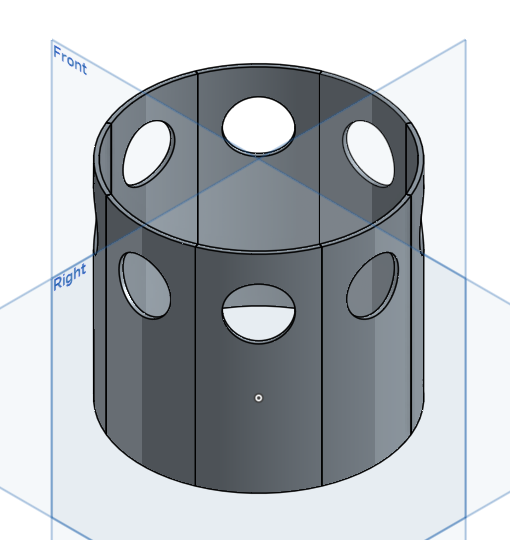

Jan 21, 2017 at 3:51 pm #3446408If you are going to do that, it seems like you could integrate the Moulder Strip into a windscreen and make it dual function. Food for thought.

Jan 21, 2017 at 5:47 pm #3446429

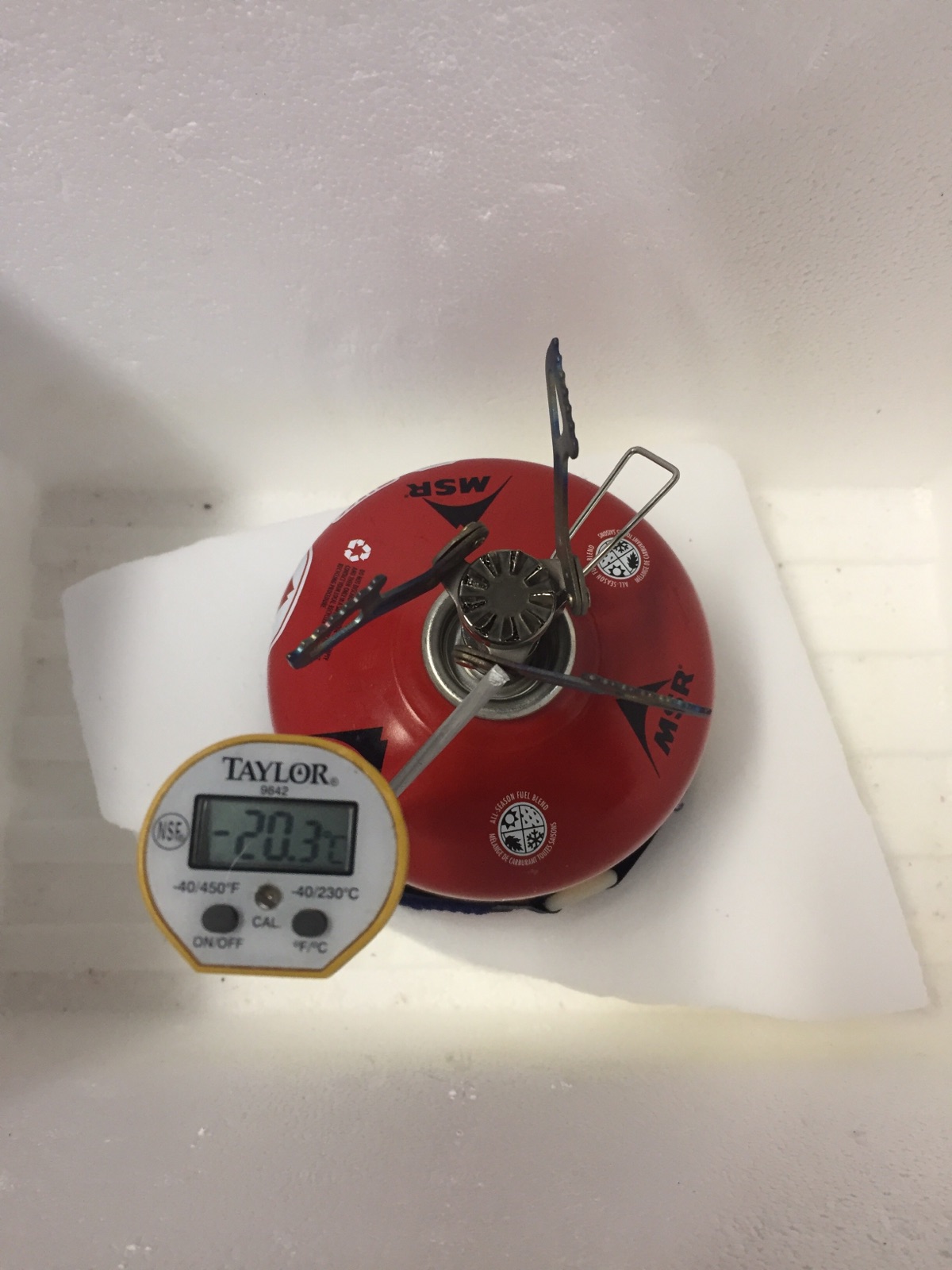

Jan 21, 2017 at 5:47 pm #3446429OK, got some dry ice, salted some water to saturation and put the dry ice in. Got the water temperature down to -14.3* C:

Strapped the thermometer to the canister and pre-cooled the stove to -20.3* C (repeated before each test):

Tried the straight single rod but only got the stove to run at about 1/2 power.

Switched to the double L rods and the stove ran at full throttle:

Tried the single L rod and got full throttle again:

Would still like to test the aluminum rods where air, surfaces and stove all start out below -20* C.

Jan 21, 2017 at 5:52 pm #3446430Interesting idea Jon. Does your windscreen come down the sides of the canister? That would make me nervous.

Jan 21, 2017 at 6:33 pm #3446439Interesting idea with rods

Hard to relate that test to how it would work in actual use at some particular temperature

Jan 21, 2017 at 7:13 pm #3446446@ Jerry: Yep. I need to visit Alaska in the winter to run real world tests.

Jan 21, 2017 at 8:03 pm #3446453I would run the windscreen down the sides of the canister, the material would be pretty thin. The holes would be tuned to let air in and to control the amount of heat transfer down to the canister. Food for thought.

Jan 22, 2017 at 12:37 pm #3446539Jon, what’s the plan to allow access to the valve without burning fingers?

Also, in a more OT vein, is that a screen shot from OnShape?

Walt

Jan 22, 2017 at 12:53 pm #3446541This was just a sketch to demonstrate a concept. An access hole would need to be designed so that you could get your fingers in there to control the valve. I suspect that it wouldn’t take much to make an effective windscreen, most of the optimization would be for controlling/limiting the heat transfer down to the canister

Yes, that is an OnShape sketch. i only spent about 5 minutes making the sketch.

Jan 22, 2017 at 11:06 pm #3446650DavidG: +1 on the aluminum version. Probably not quite as much heat moving down it as my copper wire because of the smaller (37%) cross section, but mine wasn’t max’ed at -21F so your aluminum one is probably good to at least -10F, maybe more.

But the test set-up? Nope. In actual use, one has the canister on snow at the worst and hopefully on a piece of foam or cardboard or 1/8″ plywood. You’ve got it in very conductive ice/water/brine so the heat coming down the rod isn’t just going to boil off the butane blend, but to warm up all that ice. Send me one to test, but I can’t promise more -20F temps locally (with global warming happening here more than most places, last week was the first time in over 4 years. -25F and colder used to happen a few times every winter with -40F ever few years).

Or I can beat on an aluminum tent peg and make one myself for the next cold temps or road trip to them.

Jan 22, 2017 at 11:27 pm #3446651I’ll bring my genuine Moulder Strip to the GGG David

Jan 22, 2017 at 11:54 pm #3446653You’ve got it in very conductive ice/water/brine so the heat coming down the rod isn’t just going to boil off the butane blend, but to warm up all that ice.

Yes, under those conditions with really salty water, you are trying to pump heat through a tiny 1/8″ Al rod into a great big heat sink (the water). Losing battle imho.On the other hand, the water itself will provide an excellent heat source for the canister if it’s plain water. If you have the canister sitting in plain water at 0 C you don’t really need extra heat supply if there is any propane or isobutane in the canister.

Tricky stuff.

Cheers

Jan 23, 2017 at 1:02 am #3446657With simple kits it is easy to electroplate copper, nickel, or gold onto aluminum. Would this be enough to protect it from oxidation in the flame? Those surfaces would be mirror-like and would reflect a lot of IR from the flame, though. There are also black refractory high-emissivity coatings, but I don’t know much about their properties.

Jan 23, 2017 at 1:22 am #3446659Copper might well oxidise fairly quickly if it can get some oxygen – near the edges maybe.

Nickel and gold – maybe. I suspect though that the effect will be small to zero.Aluminium in the mildly reducing atmosphere of a flame will most likely develop a good (hard) aluminium oxide layer which will resist a lot of damage. It probably won’t oxidise any further.

I suspect that it is a non-problem – no solution needed. That’s based on my experiences with my stoves withaluminium heat shunts sitting IN the flame.

Cheers

Jan 23, 2017 at 6:05 am #3446665Yeah, I believe the aluminum bars will work as well as a copper strip. A lot lighter to carry, too. Yeah the welding rod is thin. And the testing methodology not the best. But, it does sort of prove that it works. I think it would be better out of the heat sink by a lot.

Jan 23, 2017 at 7:11 am #3446672This thread is a good model for solving problems and designing a product. It’s a pleasure to read the posts in order and watch the evolution.

The posters are:

(1) knowledgeable

(2) willing to put time and effort into experimenting and discussing

(2) open to new ideas/data even (or maybe especially) when they contradict their own

(3) generous in giving each other credit

(4) Good looking

(4)

Jan 23, 2017 at 9:20 am #3446690David T: My thinking on the brine bath was to try and roughly simulate the effect of cold air surrounding the canister and sucking heat out of it. I’ll be sending you the 1/8″ rods I made. But no need to wreck a perfectly good tent stake; I dug around in my scrap pile and found some 1/4″ AL rod and beat the end flat, so I’ll be sending that too:

Roger C: Despite the heat sink, it seemed to work and not be a losing battle. But the real test will be Alaska.

Ken T: I look forward to seeing your genuine Moulder strip. Unfortunately, it’s unlikely we’ll see sub-zero temperatures at the GGG this coming weekend to test it.

Colin K: Oh man, now that I know, I NEED a gold-plated rod (to match my bathroom fixtures of course). Where can those electro-plating kits be obtained?

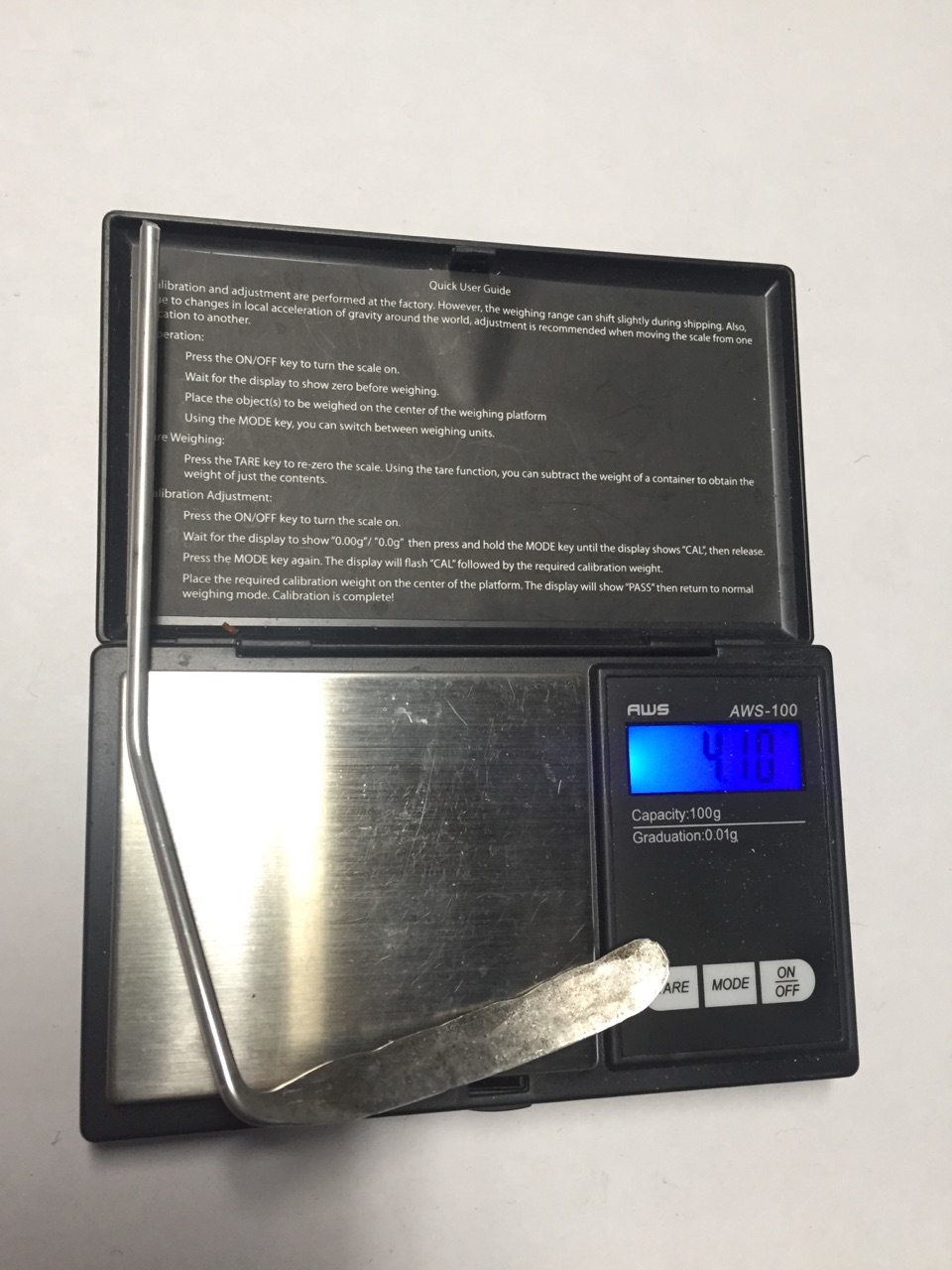

James M: Yeah, that’s what I was thinking too. If it works in a conductive brine bath it should work even better in just cold air. The 1/4″ rod I made weighs 9.75 g vs. 14.75 g for my copper strip. But the 1/8″ rod weighs just 2.75 g so it would be great if it works!

Daryl & Daryl: Interesting and fun stuff. And we are darn good looking. Buff too.

May 23, 2017 at 6:57 am #3469329Came across this today on ebay. You guys may have talked about using a magnet. This heater incorporates one, comes out of Korea:

May 23, 2017 at 7:40 am #3469338

May 23, 2017 at 7:40 am #3469338Great idea! Is there a link to the source? Do you know if it’s all copper? It looks like there may be two different metals with some kind of connector at the bottom of the neck.

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.