Topic

Any ideas how to fix this tarp?

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Home › Forums › Gear Forums › Make Your Own Gear › Any ideas how to fix this tarp?

- This topic has 16 replies, 6 voices, and was last updated 7 years, 10 months ago by

Troy Ammons.

Troy Ammons.

-

AuthorPosts

-

Apr 8, 2017 at 10:47 am #3462218

I paid a supposedly vendor a large amount of $ for a 10×10 camo sil tarp and got a half A$$ tarp. IE the edges were rolled with just one seam and the tieouts were a loop that were sewn into this seam with no bar tacks, no double stitching etc.

I explained that it would be used both rectangular and in a diamond.

At any rate I contacted them that I was not happy with the construction, and they said send it back, however, I fingered it would be just as easy to double stitch the edges and bar tack the pullouts. I also changes the corner pullouts to some that that might actually last.

I sealed it.

Then I hung it in a diamond configuration, and stretched as tight as possible, and there is a large flap in the middle. It is probalby abotu 3-4″ high.

The only way I can use it is to pull this flap over and stake it out to the side, else the flap will fill up with water.

Any ideas on how to correct this issue?

Thanks

Apr 8, 2017 at 12:30 pm #3462242Sorry, I don’t quite understand. A diamond pitch should never give you a pocket in the center. It runs diagonal from a pole/tree down to a stake. Each side corner is also staked down. It looks like this:

There should never be a chance for a pocket. If so, that means the outside edges are smaller than the tarp body… I have had this happen with stretched tarps, since I often place a stick in the center for a bit head room, room for a cloths line.

Apr 8, 2017 at 12:42 pm #3462244I think I have figured out what is wrong – maybe.

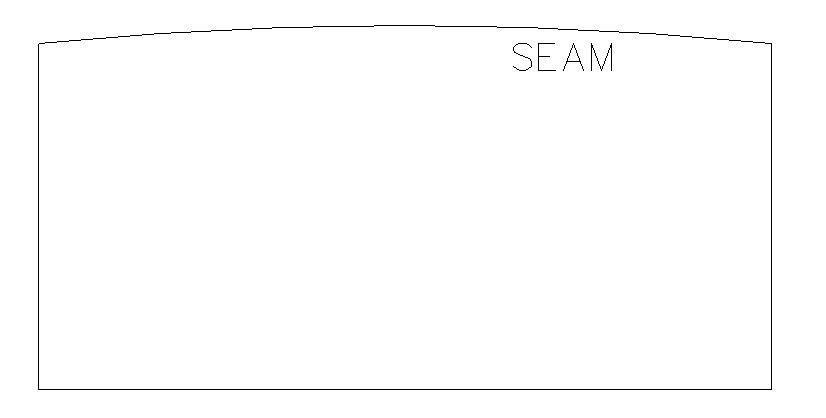

The center seam. I think the fabric is cut in a curve and not cut square, IE a reverse cat cut, which makes no sense unless whoever was trimming the fabric wasn’t paying attention..

I measured an edge parallel with the center seam at exactly 10′

The middle seam measures 9′-11″ so if the cloth was cut perfectly square then it should work on the diagonal.

It is slightly better in one diagonal than the other but not by an appreciable amount.

I think If I resew the center seam into a slight cat cut, this should fix it on the diagonal – maybe.

Apr 8, 2017 at 1:23 pm #3462255Think I have figured it out. I stretched the tarp as tight as possible along the center seam with the two sides handing, and there seems to be about 1.5-2″ of reverse cat cut.

Apr 8, 2017 at 1:43 pm #3462257Troy, pulling it tight along the diagonal, with the sides just hanging, should always result in a straight ridge. regardless of how stretched, out of shape, it is. My tarp was badly stretched in the center (9×9, center was 9’2″.) Pulling the wings out pulled a curve in it, about the same as a cat-cut would. Diamond pitches usually result in a good sleeping area, rather tight to the ground, and, a large “beak” area that a fire can be put under or near. A good pitch for spring/fall.

Apr 8, 2017 at 1:59 pm #3462264Apr 8, 2017 at 8:06 pm #3462302OK. Ignore positive or negative cat cuts. A cat cut will ALWAYS do that. In your picture, you show it inside out. It is designed never to be used in what I know of as a Diamond Pitch. But, there are several “other” definitions of a diamond pitch, it is a common name and not at all definitive. Google it. The only way it will work is as an A-Frame. Each end loop of the “cat curve” tied off to a support,or, one loop tied off and the other anchored to the ground. It is NOT a flat tarp. MANY tarps of the past 5-10 years were made this way intentionally.

You would be better off returning it, but, because you did some customizations, you cannot. It “can” be fixed. But, you have to remove the loops on the cat seam, straighten it (with a chalk line,) trim it off, open the hems, sew in a new flat seam and close the hems. Then add the loops back and seal the seam again. In my opinion, not worth it. Just buy a couple lengths of Silnylon and some loop material, and make a flat tarp. You are already doing about 1/3-1/2 the work to repair the old tarp, anyway.

I hate taking stuff apart. Especially after reinforcing someone’s bad job, only to realize I should have done more before before the reinforcements. Quite annoying. A new tarp can simply be two stitched panels (flat seam) and 1/2″ double hems all around. Then add loops as needed stitching to the hem.

Apr 8, 2017 at 8:09 pm #3462303I cant return it. Its been nearly a year. I got so mad when I figured out what was wrong I boxed it.

I have seam ripped the center seam and taken the two halves apart.

Will figure it out tomorrow.

Thanks for the input.

Apr 9, 2017 at 1:28 pm #3462394I don’t think the picture Troy posted shows a panel of a cat-cut tarp, inside out. A cat cut tarp will never have any panels that look like that, inside out or not, unless, as Troy said, it is a mistake at the cutting table. If any panel in Troys tarp looks like the picture, he has an absurdly flawed tarp, not a normal cat tarp.

Troy, given how badly made this tarp is, I assume the fabric is also crap. Hopefully it is waterproof and durable enough to salvage.

I’d suggest giving some thought to sharing the vendor who sold you that tarp. You could save others from the hassle and expense you went through. Others don’t have to lose their money, too.

Apr 9, 2017 at 2:18 pm #3462408Looking at Troy’s post history reveals the mfg.

Sorry Troy has to go through such nonsense.

Apr 9, 2017 at 2:54 pm #3462420The fabric is good to go, Camo sil.

It was only the way it was put together.

I would prefer not to throw anyone under the bus, as mistakes do happen, and they do manufacture nice gear from what I have been told.

And they did ask me to send it back.

The only reason I had it made is that I could not find anyone that made a 10×10 camo sil tarp.

If you do have something you want custom made, be very specific in what you want. Like specific to the AR degree.

Apr 9, 2017 at 5:23 pm #3462446Hey, you are right. Sorry Troy!

Apr 9, 2017 at 7:14 pm #3462467On closer inspection I found that the ends are not cut square so basically it was a sloppy job all teh way around.

That probably has more to do with my diagonal problem than anything but I still may slightly cat cut the 10′ ridgeline.

On one piece of fabric, the center length is two inches longer that the corner and that is just on that one end.

I, myself am AR when it comes to cutting ripstop and mark along a ripstop line, so its no wonder this thing wont work on a diagonal.

I guess I needed to include with my instructions to make sure it was perfectly square cut and perfectly square in general – LOL.

So now I will rip and resew this entire tarp that I paid $185 for. Oh well.

Apr 9, 2017 at 7:34 pm #3462474Please forgive the derail but I’m curious if it is ok to use the ripstop grid to cut and hem. I did this a couple years ago when my mom helped me see some stuff and I was very pleased with the results.

Is it safe to assume the ripstop grid is square?

Apr 9, 2017 at 8:16 pm #3462478I do.

Apr 10, 2017 at 11:17 pm #3462645Troy

Pending how your re-build goes, you might consider putting a shallow cat cut around the perimeter, rather than down the center. Similar (although not quite as good) effect for an A-pitch, but won’t mess w/ a diamond pitch the way a cat cut center seam will.

Matthew

I’ve found following the grid can be tricky on uncoated fabric, as it may shift on the bias. A coating stabilizes it. As long as you actually have the weave straight/square, the grid is accurate.

Apr 11, 2017 at 7:03 am #3462657Thanks

-

AuthorPosts

- You must be logged in to reply to this topic.

Forum Posting

A Membership is required to post in the forums. Login or become a member to post in the member forums!

Trail Days Online! 2025 is this week:

Thursday, February 27 through Saturday, March 1 - Registration is Free.

Our Community Posts are Moderated

Backpacking Light community posts are moderated and here to foster helpful and positive discussions about lightweight backpacking. Please be mindful of our values and boundaries and review our Community Guidelines prior to posting.

Get the Newsletter

Gear Research & Discovery Tools

- Browse our curated Gear Shop

- See the latest Gear Deals and Sales

- Our Recommendations

- Search for Gear on Sale with the Gear Finder

- Used Gear Swap

- Member Gear Reviews and BPL Gear Review Articles

- Browse by Gear Type or Brand.